At the core, AeroShield Covers products protect equipment against the forces of nature by providing the most advanced protective cover technology in the industry, conducting in-depth research on corrosion, and managing the entire protection process, start to finish.

When you need to know what’s happening under the covers

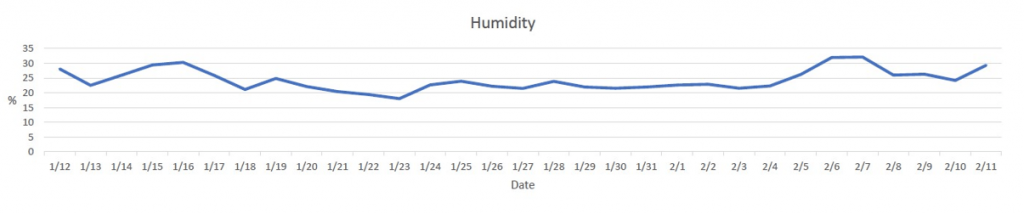

Corrosion can be deadly to expensive metal components. The industry “best practice” for controlling the humidity that causes corrosion is to add moisture absorbing compounds (desiccant) to the enclosed environment to reduce the moisture content of the air to acceptable levels. This practice is effective but requires labor-intensive manual checks and scheduled replacement of desiccant that may/may not have reached its full usefulness, or worse, has surpassed its ability to collect moisture and has allowed damage inducing humidity levels to occur. A more serious problem can result if the cover protecting the equipment is improperly installed or becomes damaged, resulting in a leak that allows humid air or rain water under the cover. This can result in an immediate increase in humidity or direct water contact that damages equipment long before the regularly scheduled desiccant replacement detects the problem.